| Teknik Özellikler | |

|---|---|

| Üretim Kapasitesi | : Ortalama 1,7 m/dakika |

| Üretim Aralığı | : DN6 – DN25, DN32 – DN50, DN65 – DN100 |

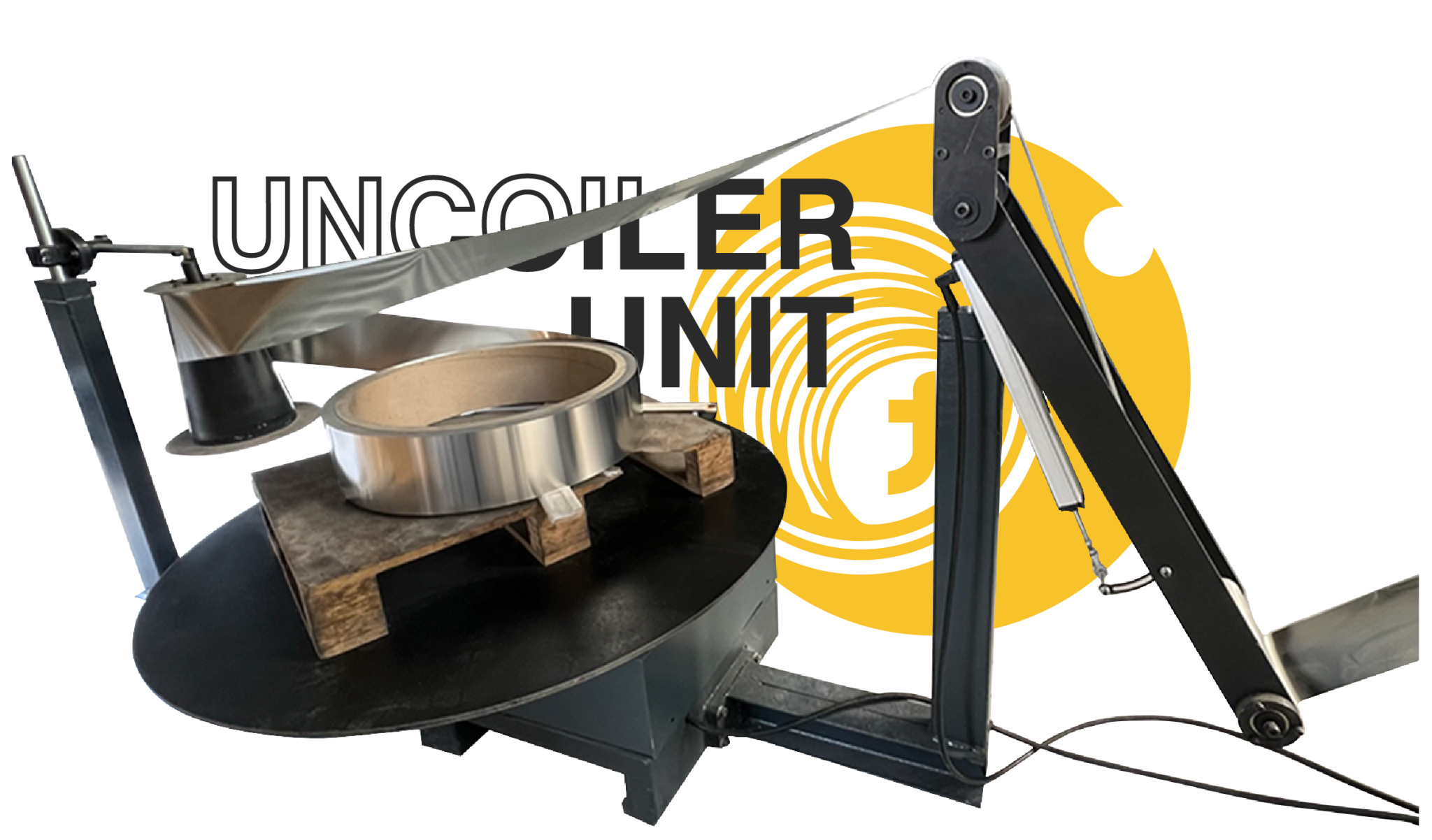

| Çelik Saç Kapasitesi | : 1,2 ton |

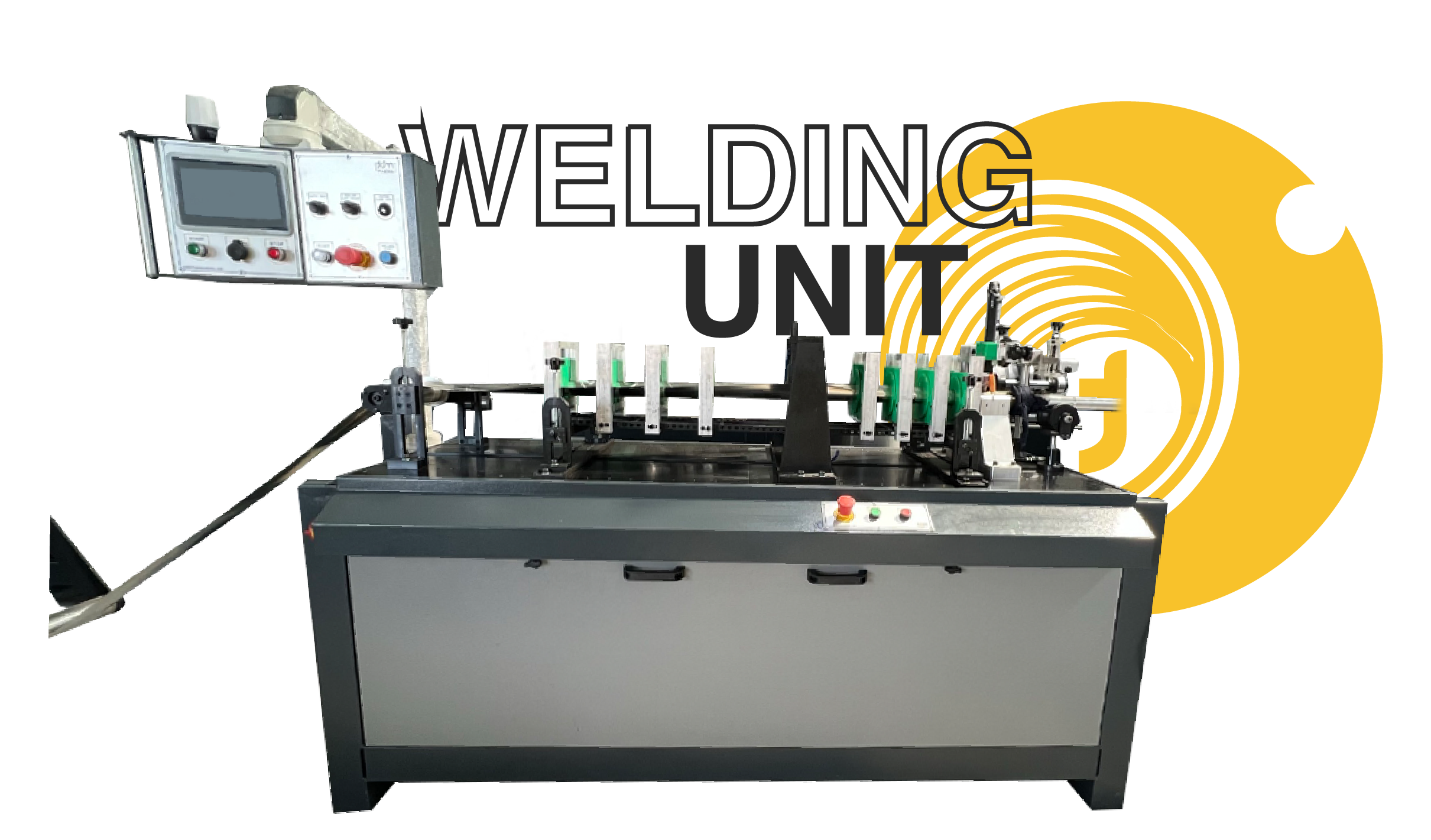

| Kontrol Ünitesi | : 7 İnç Renkli Dokunmatik Kontrol Paneli |

| Pnömatik Basınç | : 6 Bar |

| Otomasyon | : PLC Kontrol |

| Elektrik Altyapısı | : 10 Kw |

| Ağırlık | : 3215 kg |

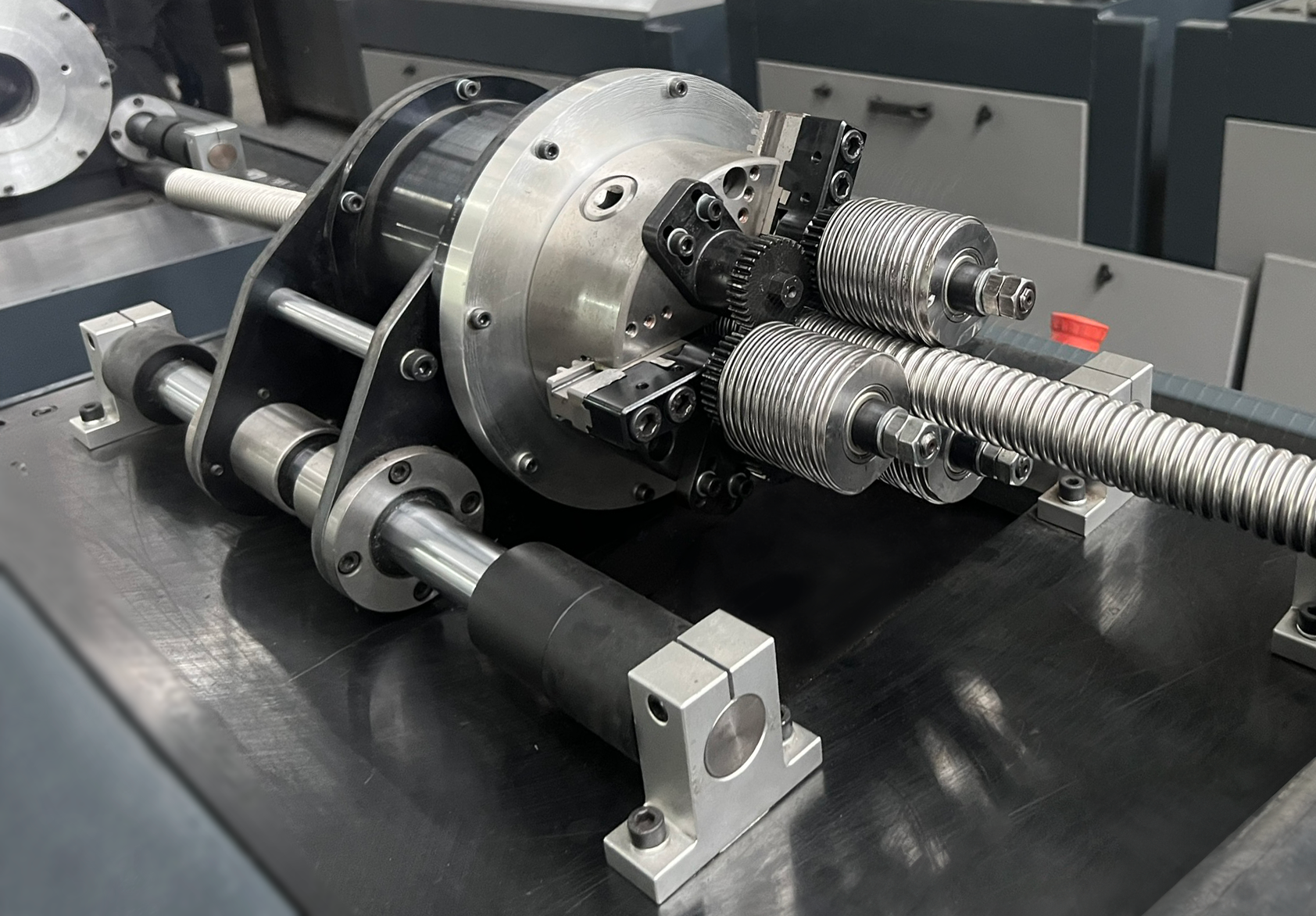

Type-25 production interval starting from DN6, DN8, DN10, DN12, DN16, DN20 and to DN25

Type-50 production interval are DN32, DN40, DN50

Type-100 production interval are DN65, DN80, DN100

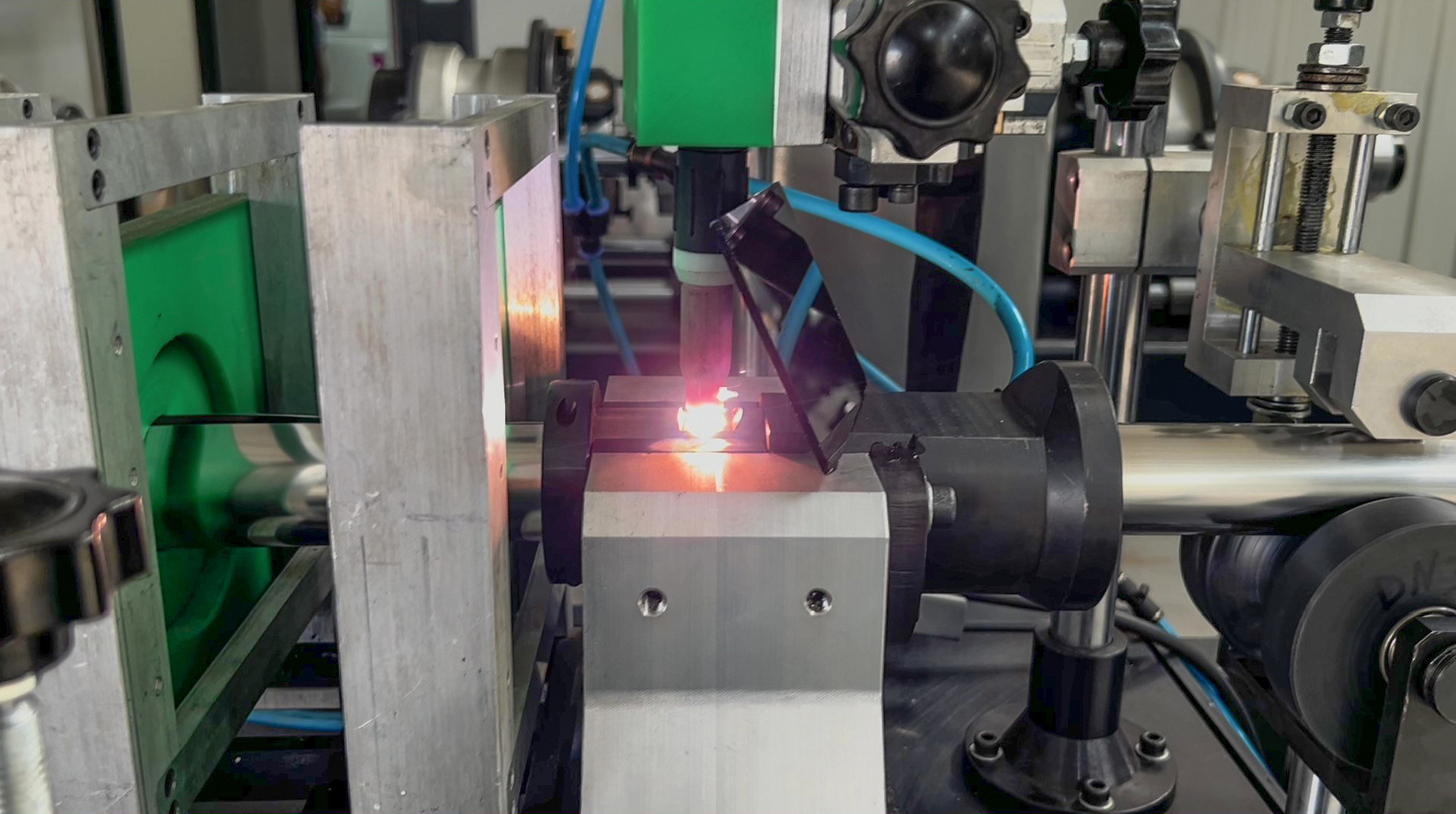

- Precision and Efficiency: These machines ensure the precise fabrication of stainless steel hoses, meeting industry standards and specifications. They streamline the production process, increasing efficiency and reducing production time. 1 operator can operate and monitor 6 machines at the same time and provide production

- Quality Control: Stainless steel hoses must meet stringent quality requirements to ensure durability, reliability, and safety in various applications such as plumbing, HVAC systems, and industrial machinery. Production machines enable consistent quality control throughout the manufacturing process.

- Customization: Different industries and applications require stainless steel hoses with varying specifications in terms of length, diameter, flexibility, and end fittings. Production machines allow for customization, ensuring that hoses meet the specific needs of customers.

- Innovation and Adaptability: Advancements in production technology allow for the development of new designs and features in stainless steel hoses, catering to evolving market demands and technological advancements.

- Cost-effectiveness: Investing in dedicated production machinery can lower production costs in the long run by optimizing processes, reducing waste, and minimizing downtime. It also enables manufacturers to scale production to meet demand efficiently.