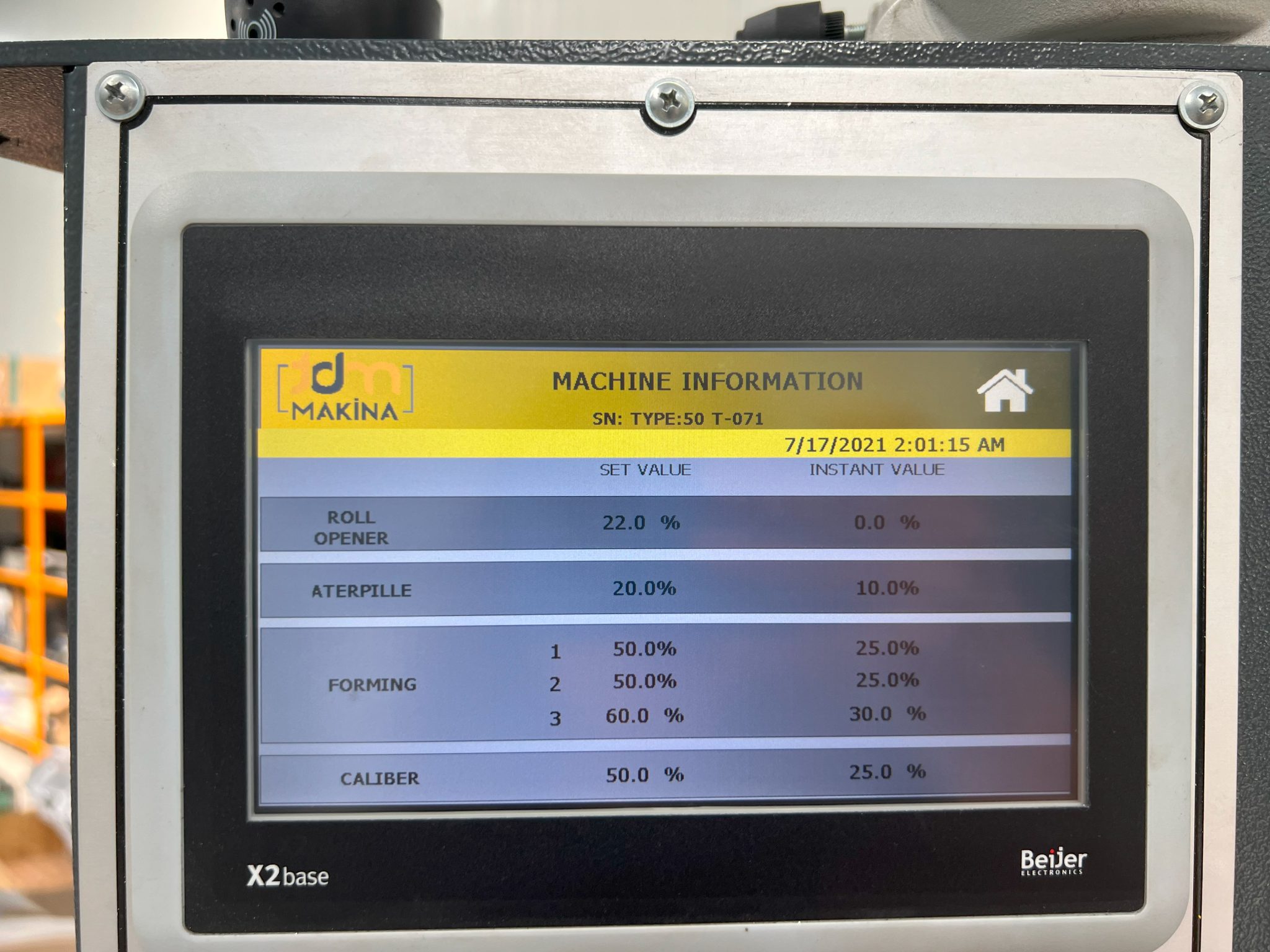

UNCOILER UNIT

The Uncoiler Unit is located at the beginning. It enables the unwinding of steel sheet rolls. It has a mechanism that opens the steel sheet by rotating around its axis at the set speed. Being made of stainless steel, it protects the steel sheet roll from corrosion.

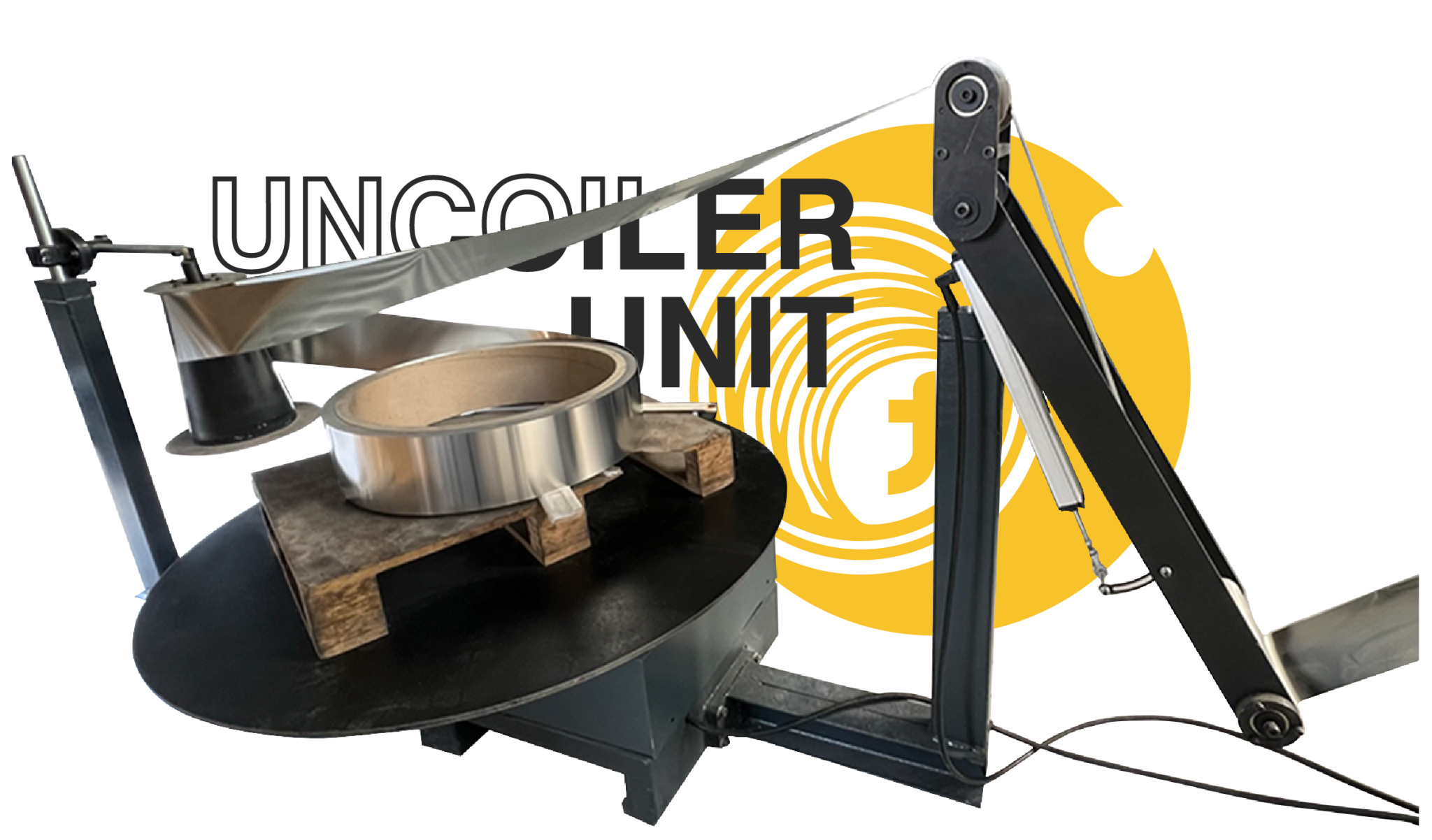

WELDING UNIT

The Welding Unit allows the fully uncoiled stainless steel sheet to pass through molds that will bend it into the shape of a hose, and once it reaches the point where it is completely bent, welding is carried out using a welding torch to transform it into the shape of a hose.

CATERPILLAR UNIT

Caterpillar(Puller) Unit; It helps to turn the sheet metal that located at beginning and into a hose shape by pulling it forward and then pushing it forward to form a flexible hose and wind it.

FORMING UNIT

The Forming Unit turns the hose from a straight and tubular shape to a flexible hose shape. The forming unit has forming stations for giving the hose flexible shaping. There are 3(forming stations) +1(caliber forming station) total of 4 pieces forming stations. The first forming station gives wide pitches to the hose, followed by step-by-step narrow pitches. After the final station (calibration), the hose is shaped completely into a flexible shape and advances to the washing unit.

WASHING UNIT

The Washing Unit cleans the flex hose produced from the line. The washing unit is divided into 2 tanks. The hose first passes through the washing tank, where the washing process is carried out by the washing airwipes. Afterwards, the hose moves to the drying tank, where it is dried using drying airwipes.

WINDING UNIT

The Winding Unit completes the production by winding the hose coming from the line. Being stainless and perforated protects the hose from corrosion.

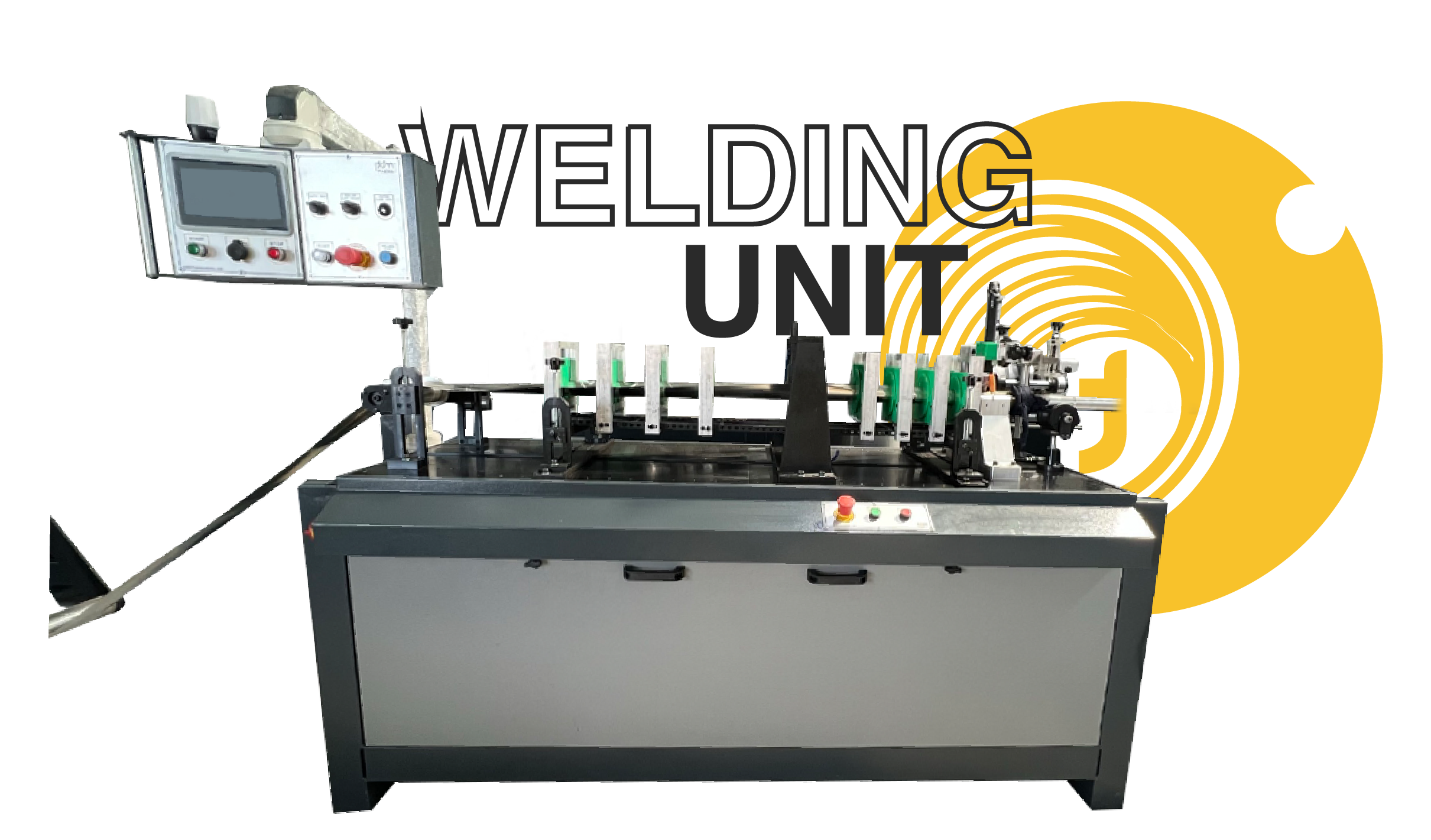

AUTOMATION/PLC PANEL

The MAIN MENU